Fabtech 2025

Unleash the spark

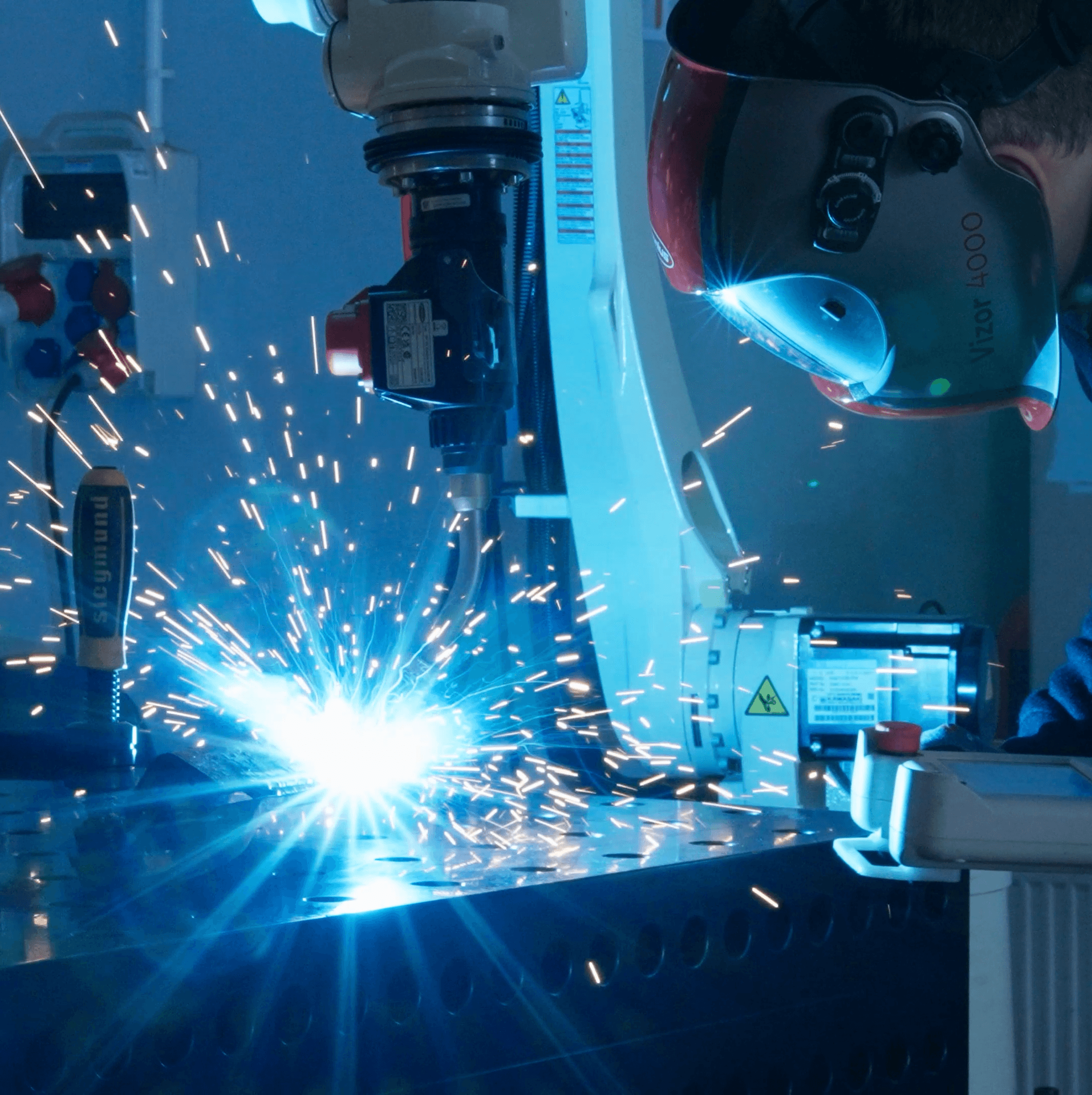

Through innovation, strength and precision, Kawasaki Robotics is igniting the future of welding and fabricating. Experience the power for yourself at FABTECH 2025 in Chicago, September 8-11.

THE 4 PILLARS

Our goal to accelerate the future of welding and fabricating is made possible by four crucial components.

- Real-world precision: With real-time path modification and a welding condition database, you get faster programming and consistent, repeatable results.

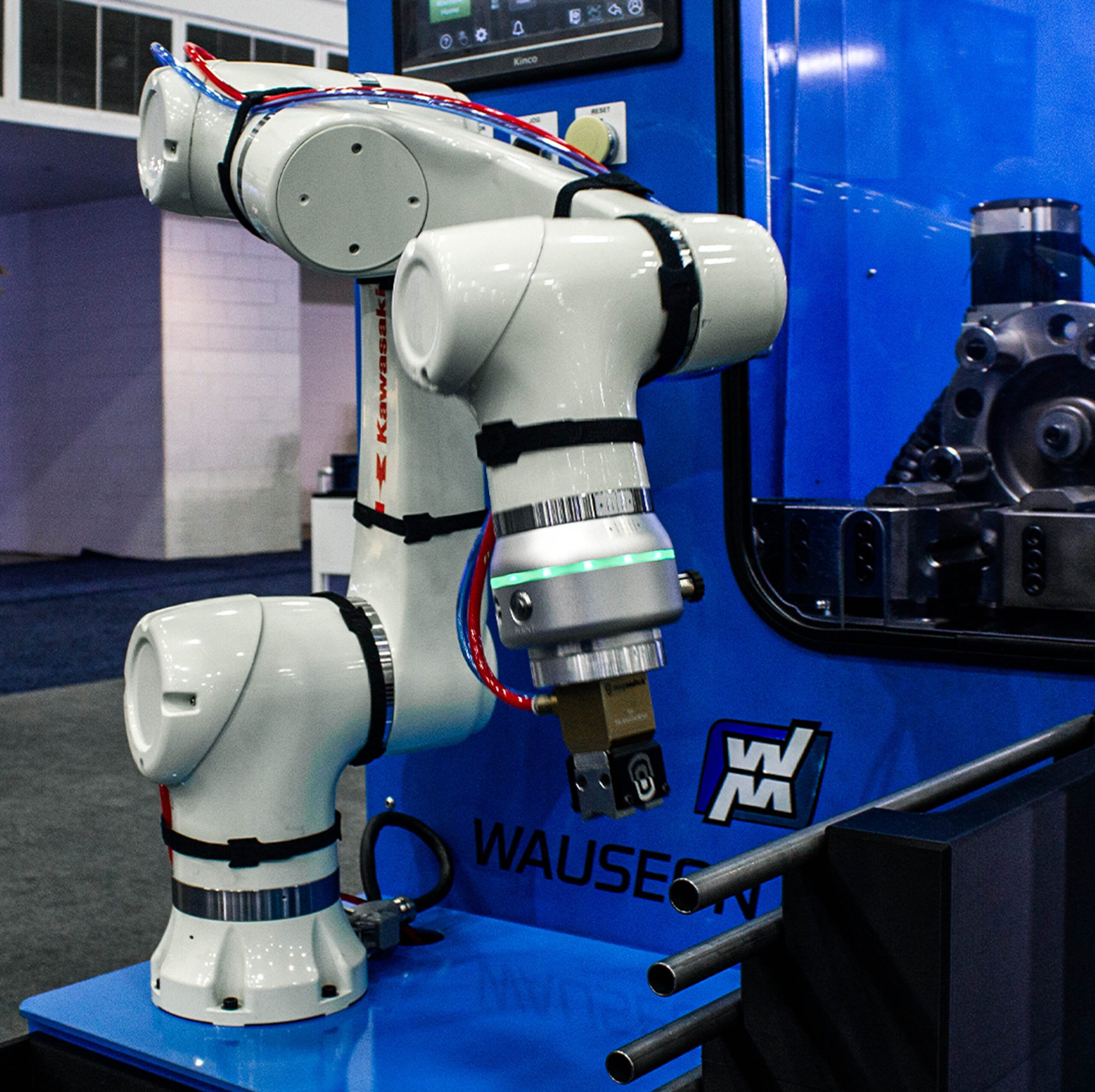

- Built for throughput: Our easy-to-use positioners and tracks, industrial and collaborative welding robots get you moving faster.

- No hidden costs: Software, manuals, training, and remote service support are included. Period.

- Collaborative evolution: exciting partnerships that push robotic welding forward

OUR TECH AT FABTECH

WHERE SPARKS FLY, INNOVATION FOLLOWS

Unleash unstoppable productivity with Kawasaki Robotics.

FABTECH 2025

SHOW EXCLUSIVE

Got Questions? No problem.

TRAINING, SERVICE AND SUPPORT

DISCOVER THE KAWASAKI DIFFERENCE

Well-trained employees are a boon to productivity, revenue and morale, and at Kawasaki Robotics, we believe in equipping customers not just with the technology they need, but the know-how to excel with it.

Upgrade or Retrofit?

Robotic Maintenance Time? Call in the Experts

5 Ways to Prevent Robotic Automation Downtime

STILL NOT CONVINCED?

KAWASAKI IN MOTION

WATCH ON YOUTUBE

IT’S DIFFERENT AT KAWASAKI

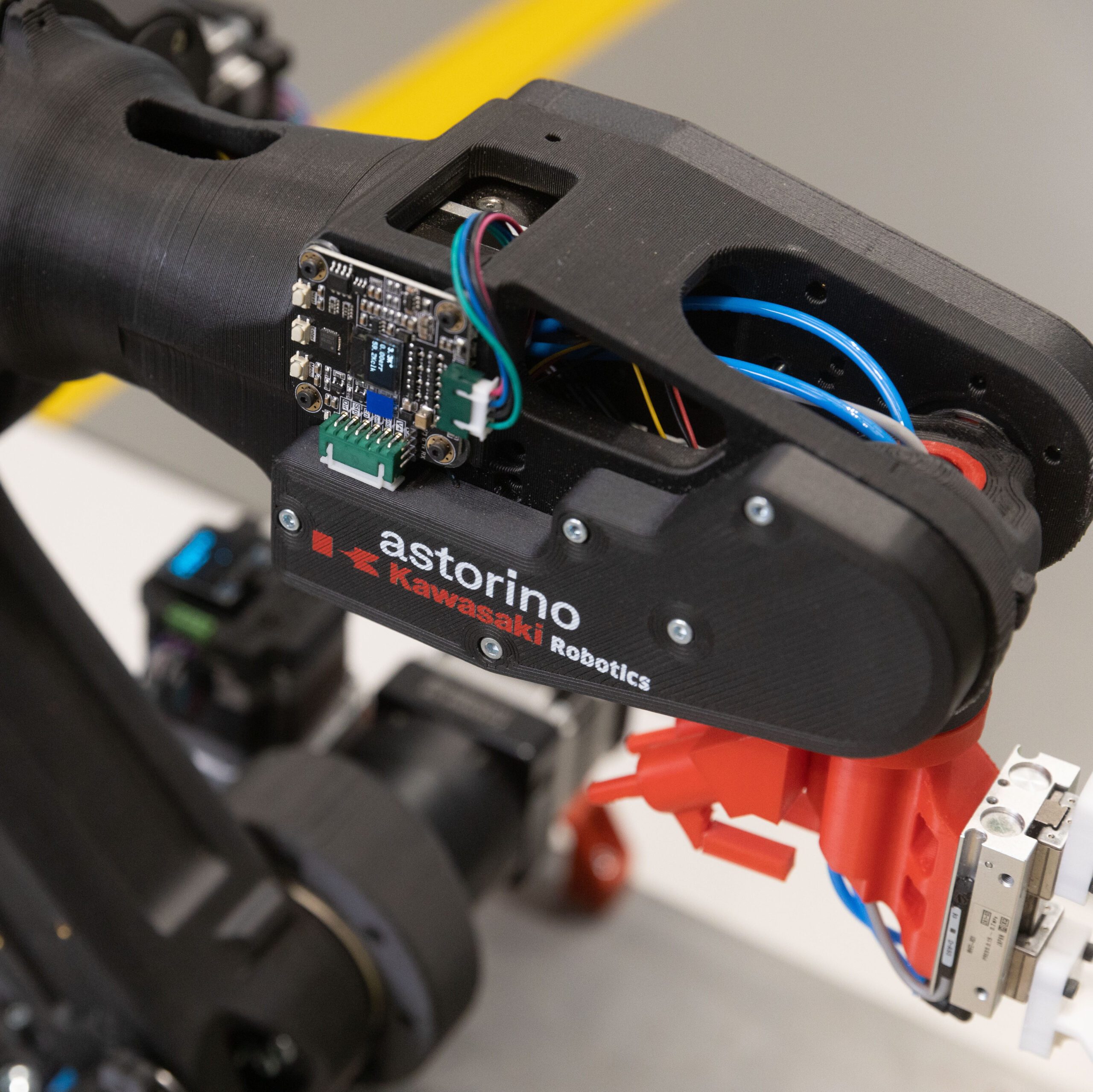

THE ROBOTS

Thoughtfully designed, built to last and always tech-agnostic.

THE IMPACT

A superior model that harnesses collaboration and partnership.

THE PEOPLE

A down-to-earth team with sky-high knowledge to share.

THE TECH

Frequent innovation that pushes what industrial robotics can do.

Case Study

ROBOTIC ARC WELDING

Experienced welders are scarce and customer demands are plentiful. Robotic welding can bridge that gap, and at Kawasaki Motors Manufacturing Corp., robot welding has been in place since the 1980s. Today, over 80 robots are welding at KMM, and we have the results from those decades of work.

Years of robotic arc welding at KMM

The amount of arc welding done by robots

FAQs

HOW TO FIND US

Find us in the B Hall at McCormick Place, Booth #B15001.

THINGS TO DO IN THE CITY

A quick browse of Visit Chicago will show you and your team the perfect outing.

MORE QUESTIONS?

Ask away! We’ll get right back to you—and maybe even add your question to the FAQ.

HEAR FROM THE CUSTOMERS

“When we first started conceptualizing this robotic house-building system, we contacted several companies but no one took us seriously. Kawasaki went as far as to simulate the concept and worked with us to the point where we confirmed that it was a technically feasible plan.”

Satoshi Kurahasi, Engineering Division Manager and Construction Division Manager of Sekisui Heim’s Kyushu plant

GET IN TOUCH BEFORE THE SHOW!

Whether you want to chat about FABTECH, ask a robotics-related question or just tell us how spectacular this landing page is, we’re all ears. Fill out the form below and we’ll get back to you.

CONNECT WITH US!