PACK EXPO 2025

PACKTIVATE!

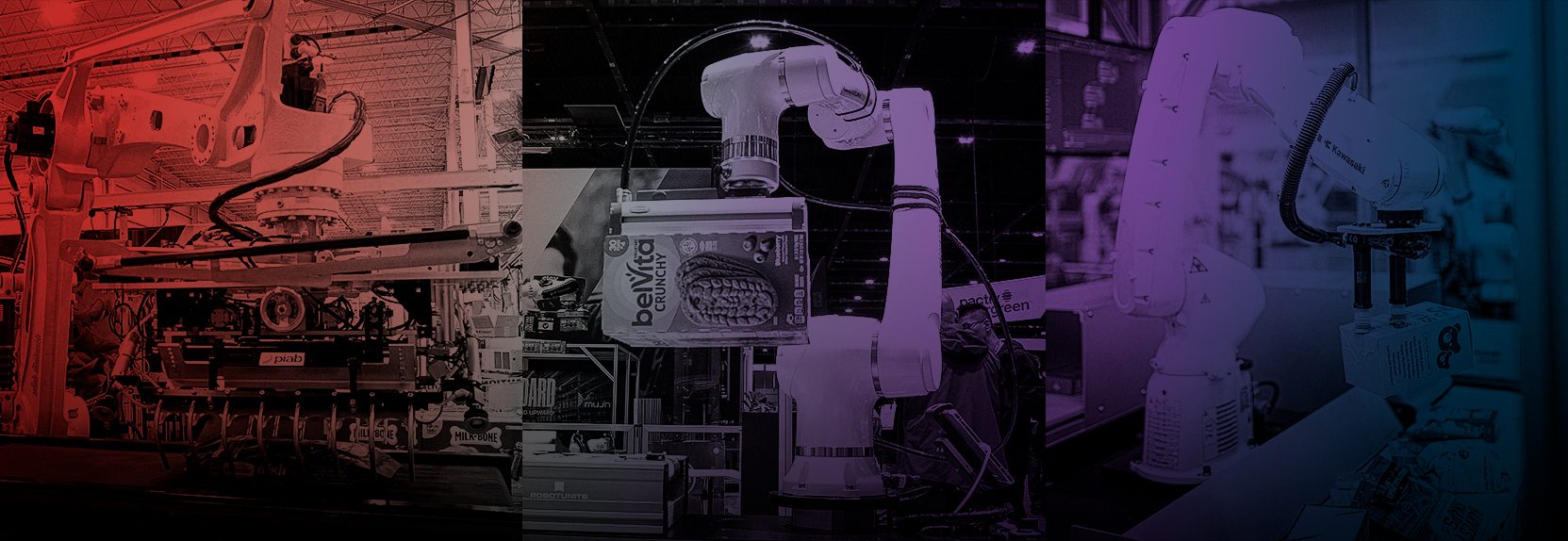

The future of packaging automation is yours to harness, and Kawasaki Robotics will help you PACKTIVATE it. Unlock faster, smarter, safer robotics for packaging, palletizing and end-of-line automation.

PACK EXPO is always high-energy and hands-on, and we’re so excited to match that energy with our famous speed, precision and quality. Let’s go!

THE 4 PILLARS

- Flexible for Every SKU: From bottles to bags to boxes, our robots handle it all. Quick changeovers and scalable systems mean you’re always ready for the next product launch without slowing down production.

- Rock-Solid Reliability: Think 24/7 uptime, high-speed palletizing and precision that cuts waste. We keep your line running smoothly so you can focus on moving more products, faster.

- Smart Connections, Smarter Decisions: Seamless integration with conveyors, vision systems and digital factory platforms. Harness real-time data, predictive insights and Industry 4.0 connectivity to keep your packaging line future-ready.

- Big Power, Small Footprint: Our robots maximize productivity while minimizing energy consumption and floorspace utilization, giving you more factory floor and lower operating costs. All in one sleek package.

TECHNOLOGY AT PACK EXPO 2025

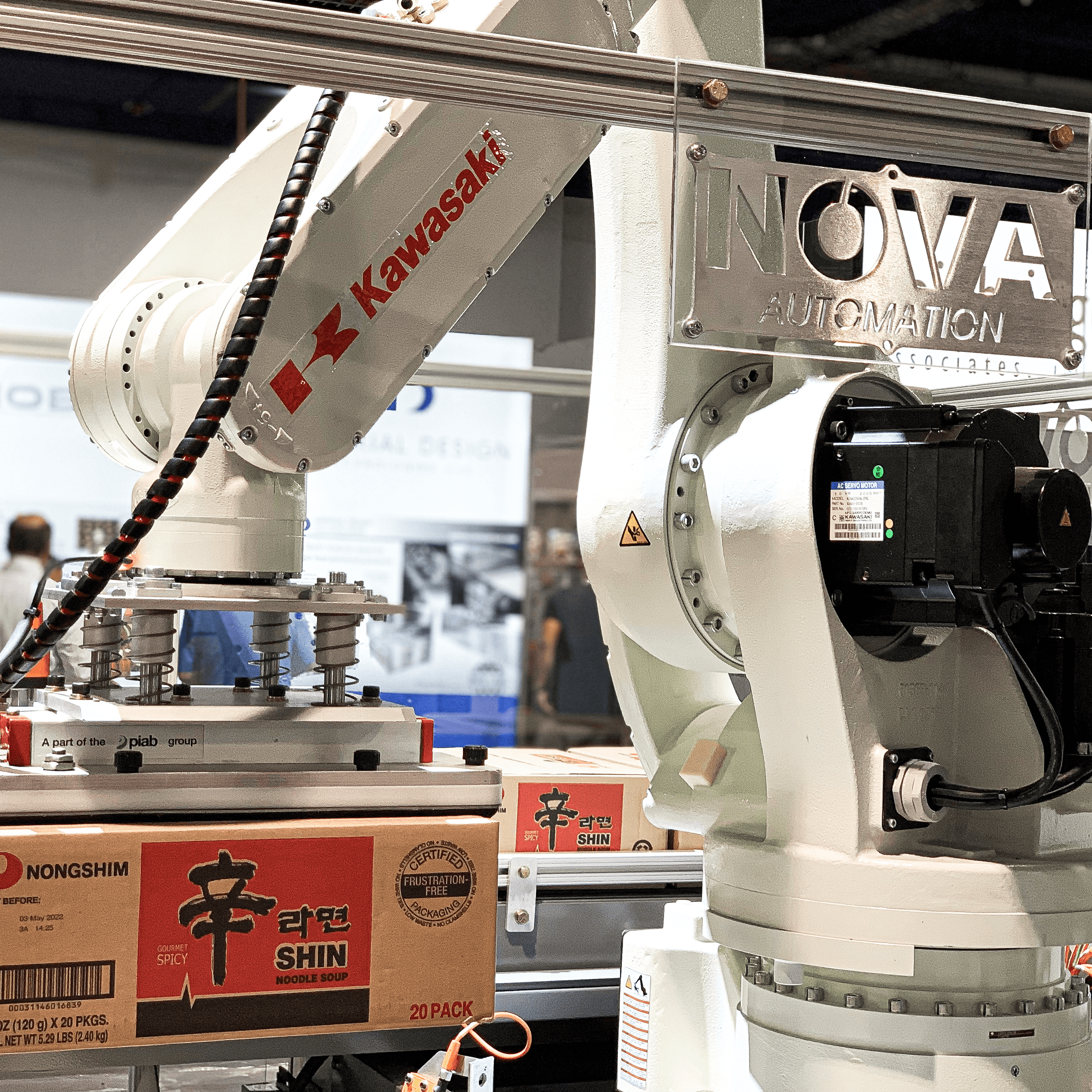

SPEED THAT ELEVATES EFFICIENCY

At PACK EXPO, see our packaging and end-of-line robots in action.

Engineered to be ready for the future of packaging automation, Kawasaki Robotics is where food safety, flexibility, reliability and intelligent integration come together for delicious results.

HEAR FROM THE CUSTOMERS

“Kawasaki is evolving their product. It’s always getting faster and easier to use. Their controllers are smaller, and they’re packing more brain power. It’s all about speed, it’s all about productivity. It’s all about production.”

Gerard Regier, President Edge Automation

PACK EXPO EXCLUSIVES

WHAT’S NEW AT THE BOOTH

WANT TO MEET AT THE SHOW?

Schedule your in-person meeting with us before all slots fill up!

Booth SL-11010

September 29: 9am to 5pm

September 30: 9am to 5pm

October 1: 9am to 3pm

Case Study

SHEARER’S FOODS

“We implemented robotics on the tortilla side of the plant. About 20 baggers feed that system so we have four robots that palletize for all those. Kawasaki made it possible for us to redeploy 46 people in the plant. And at the time we had two lines sitting idle. We were able to start those lines up. We took the plant from a $1.85 million plant to a $2.2 million plant, with a million-dollar savings in wages over the year as well.”

Plant revenue before automation

Plant revenue after automation

STILL NOT CONVINCED?

KAWASAKI IN MOTION

WATCH ON YOUTUBE

STILL NOT CONVINCED?

DIVE INTO THE KAWASAKI BLOG

Well-trained employees are a boon to productivity, revenue and morale, and at Kawasaki Robotics, we believe in equipping customers not just with the technology they need, but the know-how to excel with it.

5 Surprising Costs of NOT Automating a Manufacturing Facility

5 Ways to Prevent Robotic Automation Downtime

Where Kawasaki Robots Are Made – And Why It Matters for Performance, Reliability, and ROI

IT’S DIFFERENT AT KAWASAKI

THE ROBOTS

Thoughtfully designed, built to last and always tech-agnostic.

THE IMPACT

A superior model that harnesses collaboration and partnership.

THE PEOPLE

A down-to-earth team with sky-high knowledge to share.

THE TECH

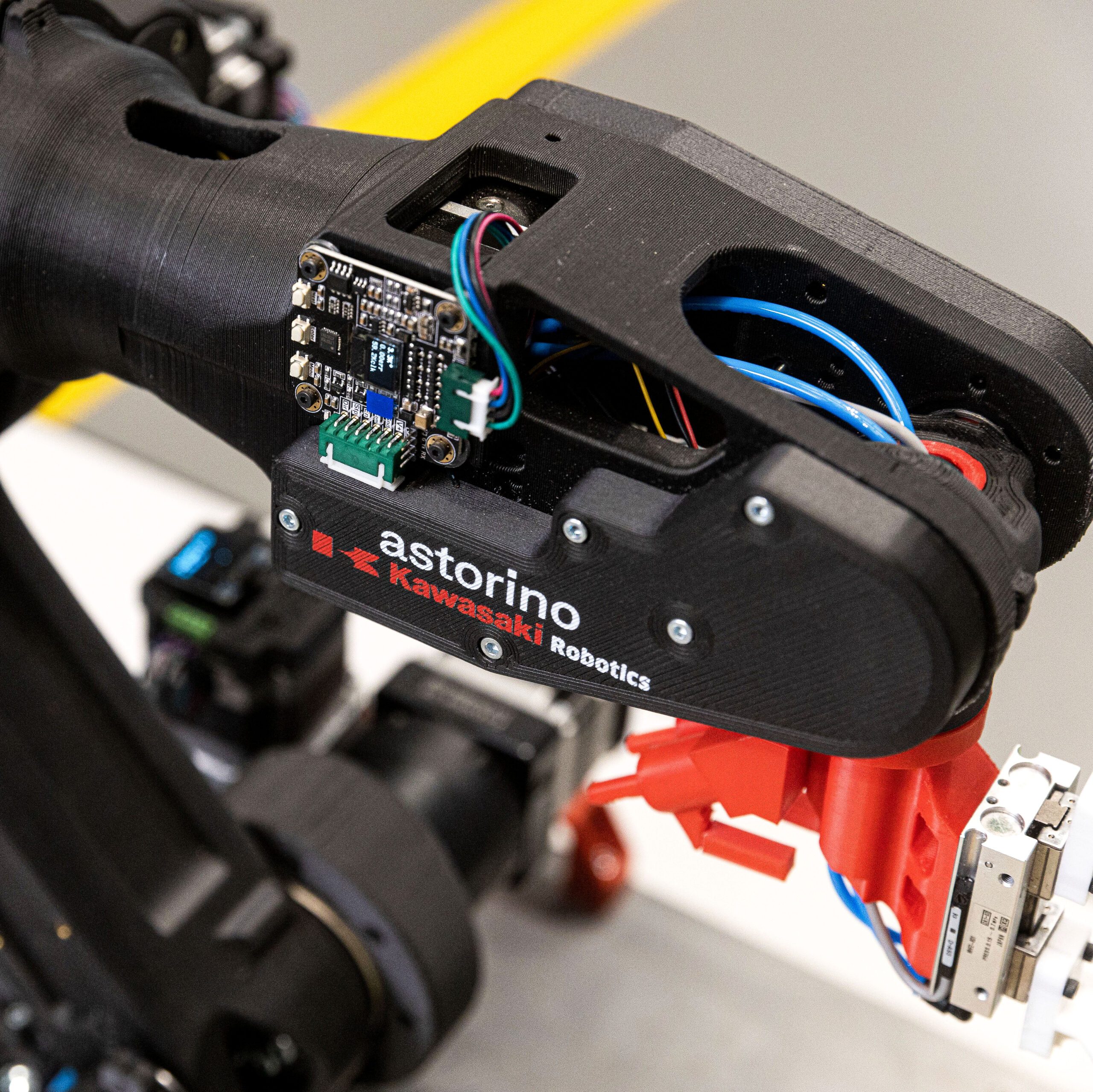

Frequent innovation that pushes what industrial robotics can do.

FAQs

HOW TO FIND US

You’ll see Kawasaki Robotics at Booth SL-11010.

WHERE THEY’RE MADE

Our robots are manufactured at our state-of-the-art Japan facilities. This guarantees precision, reliability and consistency.

WHAT HAPPENS HERE

We are a full-service hub for engineering and application design, local inventory, spare parts, service coordination, local technical support, training and certification.

OUR TWO CENTS

Absolutely a strength. Our integrator partners are how we ensure our robots are tailored to your specific need, fully scalable and supported long-term.

SUSTAINABILITY UPDATE

There’s a lot going on! Thanks to our constant efforts to achieve carbon neutrality and advance hydrogen power, environmental non-profit CPD recently named Kawasaki Heavy Industries an A-List Company.

THINGS TO DO IN THE CITY

Las Vegas has something for everyone, but here are Trip Advisor’s picks to click.

MORE QUESTIONS?

Ask away! We’ll get right back to you—and maybe even add your question to the FAQ.

GET IN TOUCH BEFORE THE SHOW!

Whether you want to chat about PACK EXPO, ask a robotics-related question or just tell us how spectacular this landing page is, we’re all ears. Fill out the form below and we’ll get back to you.

CONNECT WITH US!