Do you have any of the following problems

with visual inspection?

A chronic shortage of inspectors.

A limited number of employees with inspection skills.

Shortage of manpower is causing problems of daily production.

Inspection by a robot and a camera

Because a robot and a camera perform inspection instead of workers, there is no need to rely on the technical skills of workers. Unforeseeable circumstances such as sudden vacancies can be avoided.

There is variation in inspection quality.

When performing visual inspections, there is a decreased yield due to different standards among workers.

Improving yield and stabilizing quality

By achieving stable inspection quality by introducing a robot system, you can operate the production line in a predictable manner. In addition, the variation in inspection standards is reduced, leading to improved yield.

Since there is a variety of parts, dedicated machines cannot be used

A dedicated machine is required for each part.

The facilities become complex and large, and expensive

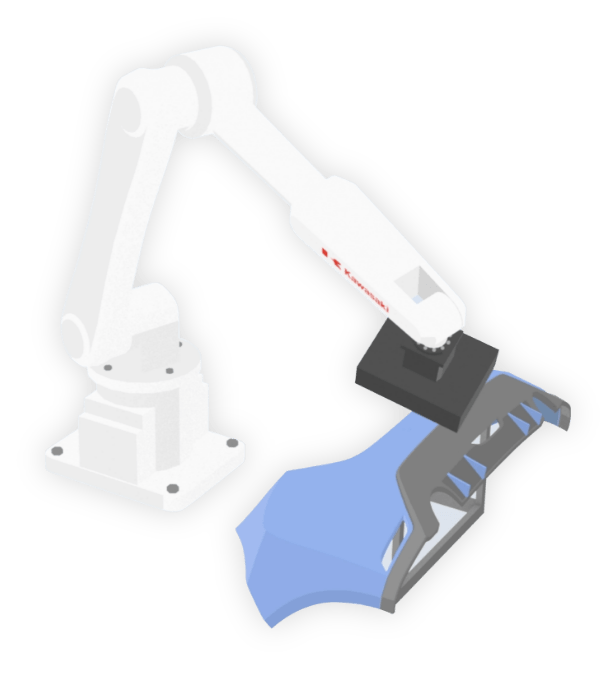

A single robot can handle various parts.

By using a highly flexible 6-axis robot, the system can respond to any changes in parts. Since there is less programming required, the startup period can also be shortened.

high-speed visual inspection system

can solve your problems!

Kawasaki original

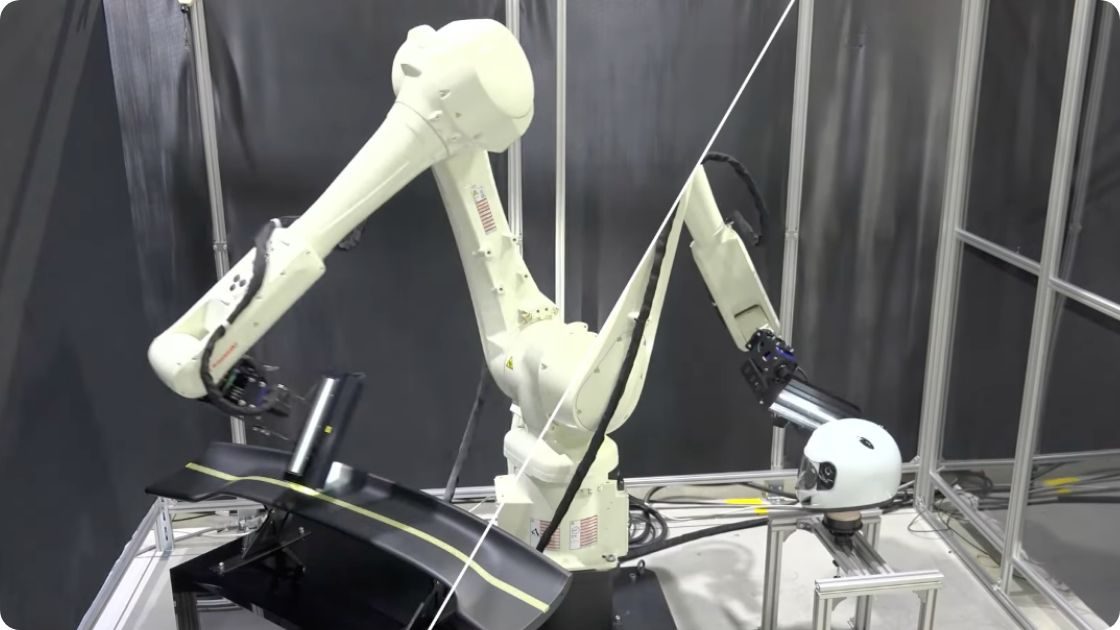

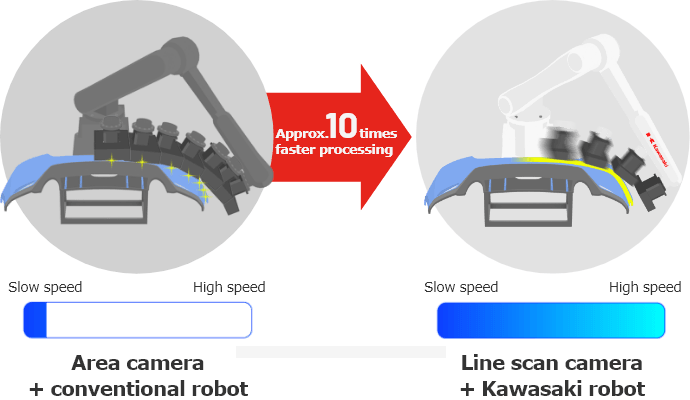

scanning visual inspection achieves high-speed operations.

Conventional technology could take image a narrow area only, taking a long time to inspect. Because of this, automation did not proceed. However, the newly developed high-speed pulse-output function enables high-speed image scanning while moving on the product surfaces at high speed.

Kawasaki’s scanning type inspection system can

inspect curved surfaces quickly and accurately

without stopping.

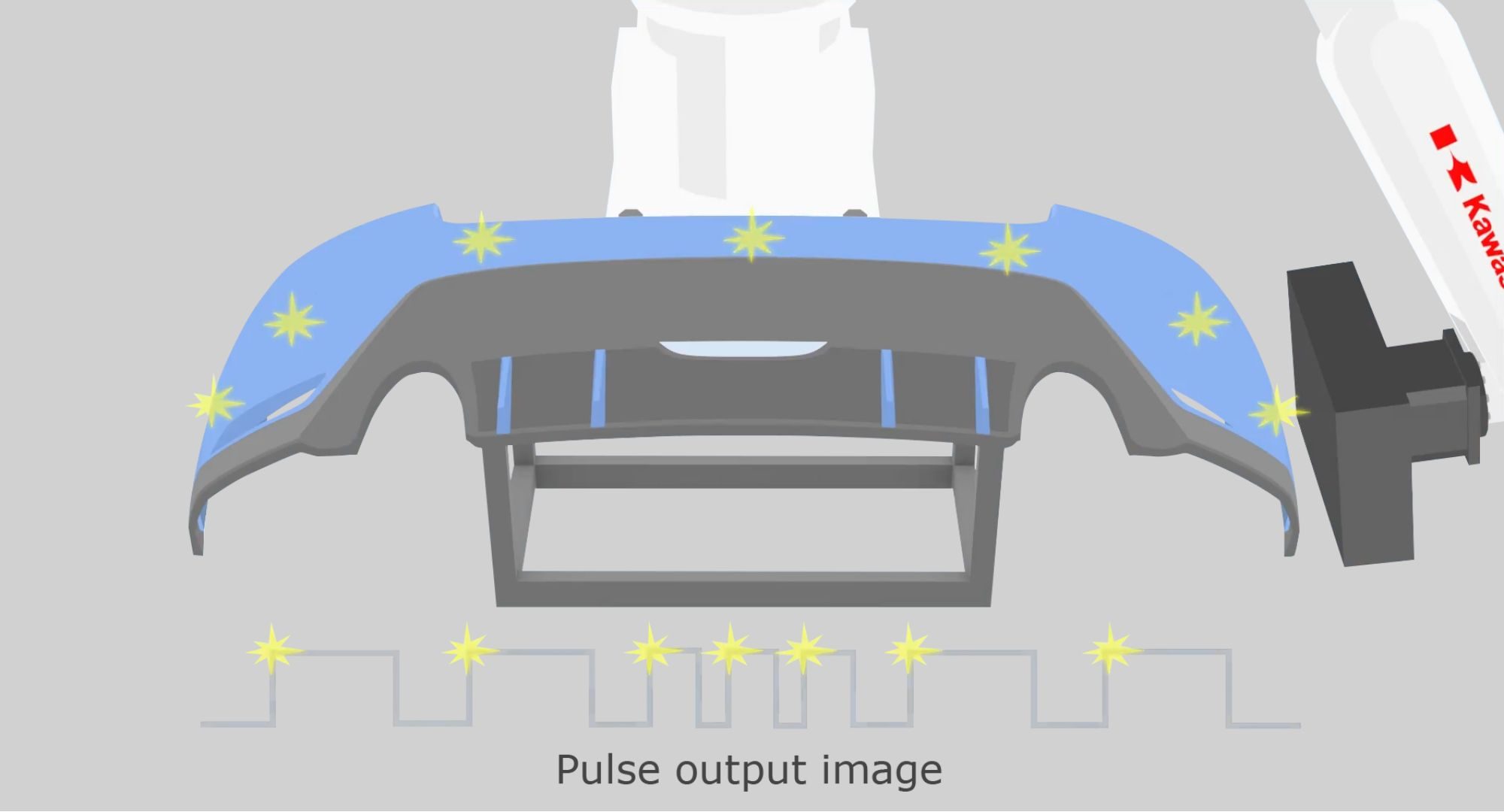

High-speed pulse-output function

By outputting pulses at high speed,

the performance of the camera is optimized

even for parts with curved surfaces

to be inspected!

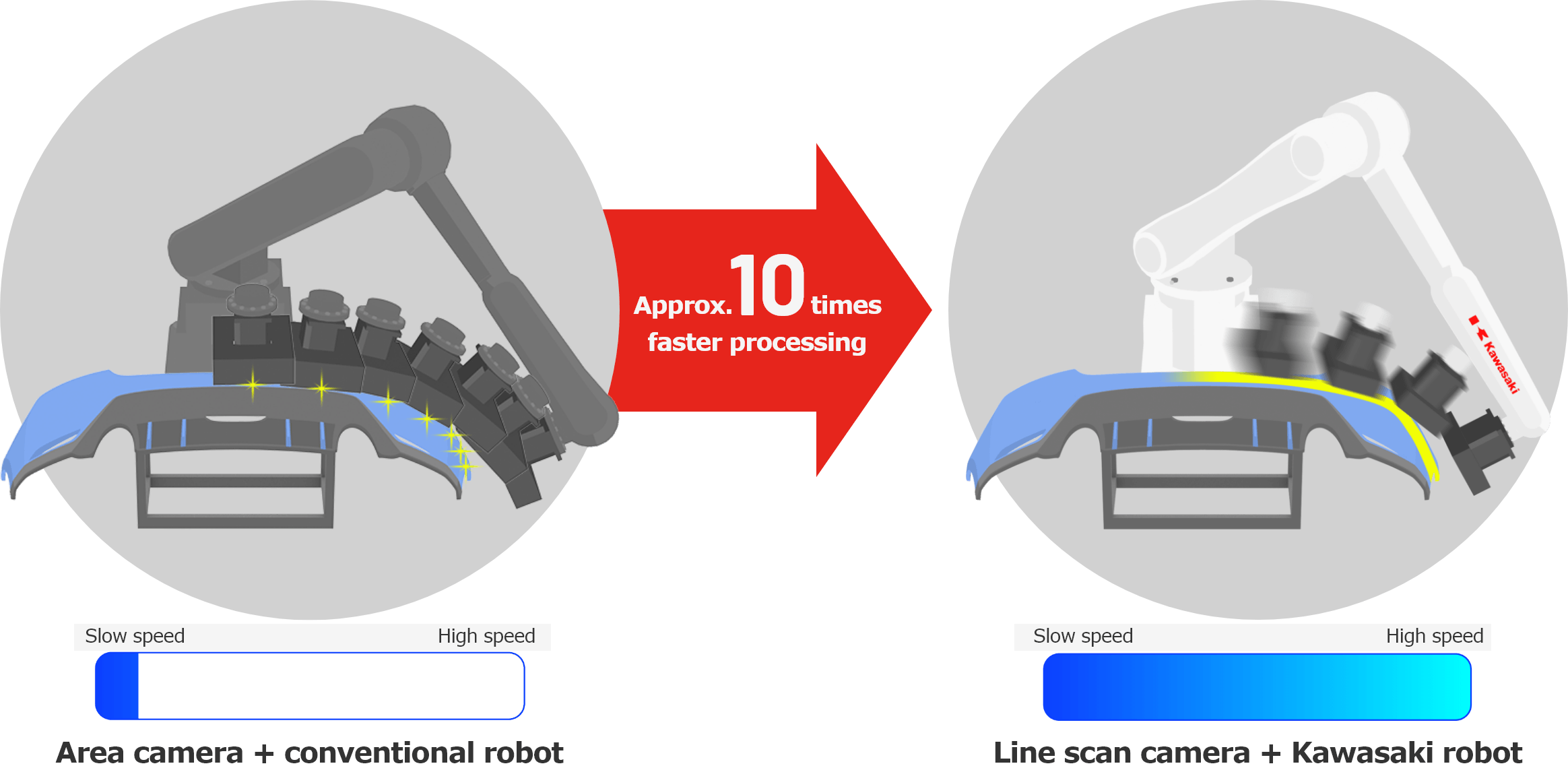

Comparison with conventional inspection systems

Process of introduction

Kawasaki will support you from the initial contact to implementation and start of operation!

Contact

Please feel free to contact us if you have any problems with your visual inspection, or if you are interested in Kawasaki Robotics’ visual inspections. Our representative will contact you.

Proposal of the optimal plan

After hearing about your problems and the necessary information (e.g., the workpiece data, defects to be detected, your introduction schedule, etc.), we will propose a path for introducing the robot and verification steps.

Image capture trial

We will conduct a simple trial to see if the defects in question can be detected. For this trial, we will ask you to prepare a flat test sample.

Robot vision trial

We will conduct an image capture trial using a 6-axis robot and the actual inspection object. We will verify the cycle time using the actual robot and vision system.

A robot system is proposed.

Our partner integrator (SIer) who is well-versed in both cameras and robots will propose the optimal robot peripheral equipment for you.

After-sales follow-up

robot service team will provide you with a quick response and optimal spare parts proposals.

FAQ

Q What is the difference between an area camera and a line camera?

Area camera: Images objects in a 2D plane like an ordinary camera (tact time is slow because the robot arm stops to capture images).

Line sensor camera: Images objects in a linear motion, like a scanner (tact time is fast because the robot arm can move while scanning).

Q What kind of line cameras can be connected?

Any camera that accepts pulse input can be connected.

Q Any camera that accepts pulse input can be connected.

This is a patented technology of Kawasaki Heavy Industries. This function outputs pulse signals in real time at regular intervals of the movement of the robot’s tool tip. By using these pulse signals as the trigger for image capture, it is possible to capture images uniformly regardless of the speed of the robot’s movement.

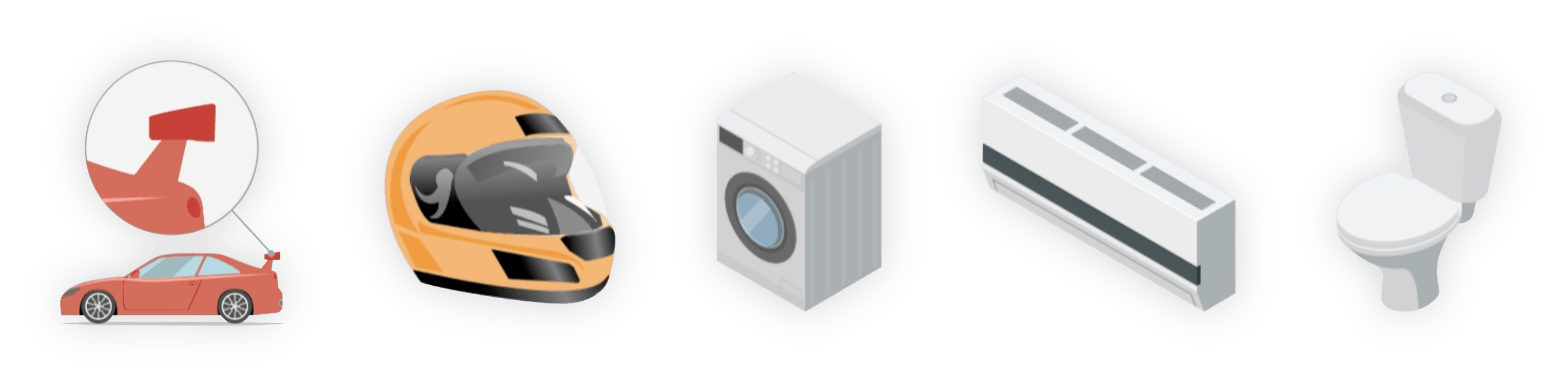

Q What can be inspected?

Materials: painted parts, resin molded products, ceramic products, composite materials such as FRP, iron products, etc.

Contents: scratches, dirt, dents, burrs, deformation, paint defects, etc.

Q What sizes of workpieces can be handled?

It depends on the robot’s motion range (robot models compatible with the F controller only).

It is also possible to handle external axes such as travers unit.

Q Is a verification by actual robot performed immediately? What is the steps for moving forward with a project?

For the verification, we will provide a quotation after checking the workpiece information, tact time, schedule, etc.

Contact

For more information about our products and services, please contact us using the form below.